I’m sorry you took it that way, that’s not how I meant for my little rant to be received. I started with a joke and expected the rest to be received at about that level.

I don’t know what experience you have, I’d expect you to be an engineer or learning to be to start a project like this. I’m an engineer myself, studied mainly digital electronics. I’m very aware of that I don’t know everything there is to know and for almost every project I’m in I learn new things from older co-workers. “We just used to do like this when I was working at… ” here or there. Maybe it’s a very simple solution that is quick to implement.

… I’m having to make right now is how to deal with the SRAM chip, since it requires power to maintain data. That makes it very hard to debug because I have to debug it live in the system.

My interpretation is that you weren’t familiar with the way to make a battery backup and I thought I might as well present the solution for you and all other people reading (or I would have sent it as a PM) so you/they wouldn’t have to google for it. Nowadays a flash rom is usually what you find in stuff.

I thought there was a problem, I wanted to offer a solution. Not trying to push you down or claim I know more or that I’m better than you – I wouldn’t attempt this project myself as there are too many details I’m not familiar with.

BTW, if you were already familiar with the battery solution, why hadn’t you hooked a battery there already to be able to debug it when it’s not live?

[joke]

I tried explaining it to my five-year-old daughter, she didn’t get it, not even when I translated it into Swedish, I think you’d need to be at least 10 with some basic electronics knowledge.[/joke]

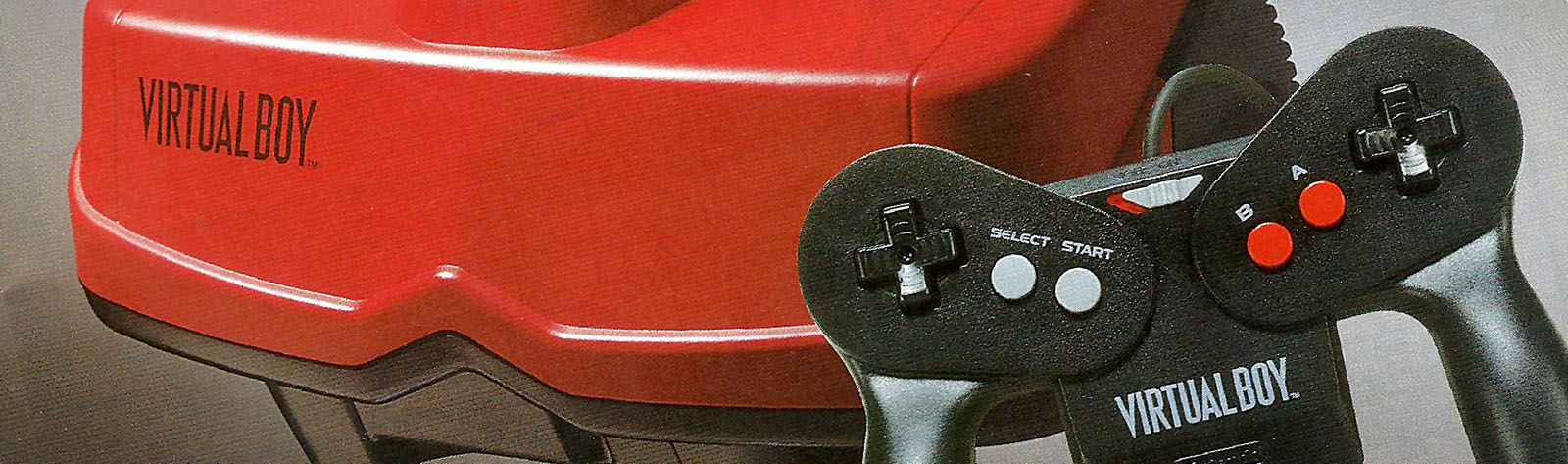

I think any normal person who had plans to make some type of multi-cart for the Virtual Boy would wait and see where this goes first as it’s the best solution anyway. I didn’t think it was any idea to do any more work on a static multi-cart if there’s one coming up that reads it from a microSD card or similar.

Regarding Minestorm’s probable already finishing a cart, I just meant that as he has done many parts/blocks of such a project already it would be easier for him to put those together (I’m guessing) and that you shouldn’t be deterred to keep at it even if it takes time as you’re starting from scratch. If you want to make a similar project for another console you already have a base and wouldn’t need to start all over again – so next time would be quicker. Not that there’s any hurry, as Minstorm said – it’s for fun, and I hope it’s still fun for you at times. The boring part comes after a bunch of carts when you’re just building and delivering the stuff.

I’m sure several people here, some other people who has found your blog and also including myself is quietly cheering for you and your effort so far and hope you’ll stay at it and offer us the last cart we will ever need for the Virtual Boy.

So nothing negative was meant on my part. I’m not afraid to write very clear if I mean to be evil/pissed off/grumpy/etc.

I usually try to be cheerful and helpful online and I hope everyone who reads my messages has that as an initial point of view. I hope noone who has some history with me at this or other forums thinks anything else.

So all my best to you, if you want some pointers or help, don’t hesitate to ask us other engineers here.

Anyway, back to the PCB-plant, “holding my thumbs” that you’ll be able to solve all little problems you run in to. I think we know how it can be when you wrestle with a single little annoying detail for weeks – better to have it sorted out before it’s done, debugging can be even more time consuming.

What, are you spending your own money!!?? 😉

If you’re short on cash perhaps asking for donations alternatively some kind of kickstarter project or maybe pre paid orders would help.

Of course it’s a lot of work if you haven’t done it before, that’s always the case. Not just the hardware which can take a long long time to CAD when you’ve found the parts you need but all the software as well.

If you weren’t making one I’m sure Richard would have made one by now as he already have most parts of such a project done with FlashBoy and also his Vectrex cart with microSD card reader. I don’t think the market is that big so you probably need all of it yourself if you want to make something from the invested time and money.

Regarding the SRAM issue, already in the 70’s (maybe earlier) they used a battery and two diodes, it should still work… Diode prevents current to flow into the battery, a current limiting resistor could be added to prevent smoke and melting things if there’s a short…

You need a second diode for board VCC to block the battery from powering the whole board.

VCC of SRAM —-|<---- board VCC VCC of SRAM ----|<---- battery + GND of SRAM ------------------------ battery - I was considering using something similar in my Fairchild carts but I decided to try out FeRAM instead which worked out pretty well although they are quite expensive. I saw a RAM cartridge (game copier) for Commodore 64 that worked the same way, holding the memory with a battery. This should hold the SRAM powered for a LOOONG time (if it's a 5V SRAM) http://se.farnell.com/productimages/farnell/standard/42245229.jpg

So what can we do to ramp up your motivation? Not that I have the money right now to get one of these so on my account you can work on it a few more months. 😉

I was thinking if it would be possible to use the CAD:ed connector by one of our members and then try to find the female end of a PCMCIA connector (only the metalpieces that are in the connector) to make proper connectors. The type you have previously linked to worked most of the time on my veroboard built eprom cartridge but it would be nice to have something original looking that works all the time, even if you happen to bump the cart.

Richard, who made the most excellent FlashBoy and also VecMulti among other things ( http://www.vectrex.biz/ ) refrained from making an SD card based cart because of this project, so lets hope Vaughanabe13 gets this together soon, preferably when I happen to have money to buy one. 😉

If you get tired fast then a cart with everything on it is a good thing but if you play the same game for a long time I don’t see anything negative with having just one game at the time.

So, what kind of mod is planned?

Looks pretty nice, perhaps it should be a more American looking label with the usual background?

EDIT:

Here’s my almost clean background that I used to make a 1200dpi Bound High label. Had to save it as jpeg to be able to upload it.

http://postimage.org/image/v7nej2y0v/

I thought I had made a completely clean one but I can’t find it right now.

Cool… maybe it deserves a cartridge of its own. 😉

Connector pieces in a PCMCIA card is about the same size, maybe it’s possible to find them loose somewhere.

I was wondering about the connector piece, if it was possible to find a properly fitting connector piece like these (which are probably too large)

http://ultimachine.com/content/01-gold-female-connector-pack-100

It doesn’t actually have to be a round female piece, perhaps a “double tongue” would be enough.

There are places to have these things manufactured of course, IMHO it would be very neat being able to build a cart from all new parts.

First valid reason I have seen to get a 3D TV! Compete in VB games with friends in a social manner.

Nice, like the mockups, should be done for all of them.

Making 50 of these or so should get you some discount on parts at least. But see if you can get everything working and we can bother about cost reductions after that.

Either you’ll go through all the troubles with casing, labels etc or just sell it cheap as a bare board and leave it to others to do the rest. There are some creative people here that usually take care of such things. 😉

I’m guessing over $100, which is OK for me, if they’re cheap we can buy more… 😉

Looks nice, we’re all hoping for an affordable price and no need for updates. 😉

There are people with crates of brand new Virtual League Baseball, I recommend start looking here:

http://www.ebay.com/ctg/Virtual-League-Baseball-Virtual-Boy-1995-/5566?rt=nc&_cqr=true&_dmpt=Video_Games_Games&_nkwusc=virtual+baseballe&_pcategid=139973&_pcatid=2&_pdpal=1&_refkw=virtual+baseball&_rusck=1&_trkparms=65%253A12%257C66%253A4%257C39%253A1%257C72%253A6063&_trksid=p3286.c0.m14

For $20k you’d probably be able to make 700 of these sets. IMHO the community is too small for 700 carts… So Shapeways is a good alternative, donor carts are however cheaper.

The connector I found is not recommended, needs tweaking before it works well. Finding a suitable metal connector for a Shapeways made connector strip would be better.

Guess they need to be made from a material with higher resolution.

Here’s the updated bottom shell

http://www.shapeways.com/model/525467/6b33b163341aba655812fda0f463da29

Ask Alistair McKee if you want to have them made.

I wonder if it could be polished or enhanced with some transparent acrylic paint…

Looks nice!

There are a lot of different materials, did you choose the “Red Strong and Flexible”? Wonder how it would look in “Black Detail”…

Yes, the three little holder pieces are missing from “VB cart body rear (no text).STL” if the maker sees this perhaps it can be corrected – have been searching all over but I can’t find it. 🙁

Not that the current version won’t work – it will but it will be possible to pull the edge apart.

Make a mold and encase it in epoxy… 😉

I’d be happy to buy a naked PCB and transfer a connector and shell myself, there’s a lot of brand new V.L. Baseball carts out there.

I never got a reply from my contact in Thailand about making a cartridge shell. Perhaps some place where they make 3D prints will be an option if you want to make something brand new.

Looks promising, making all those footprints that aren’t in the library already is a real pain.

I wonder if there’s some central deposit for those things so you can upload and get other people’s stuff?

You should perhaps try and find some cheaper PCB manufacturer, I order from China when I build carts for the Fairchild Channel F and prototyping is done. Recent purchase was for 14 PCBs, plain double sided (basically cheapest alternative):

1) FRCJ01 2.28

2layers, 0.062″, FR4-TG130, 1oz, Lead Free HAL, GREEN SOLDER MASK, WHITE SILK SCREEN, Complex Shape, 3.50″ x 3.15″ Special Notes: Shipped As Individual Boards , Ship To Sweden

QTY: 14pcs USD11.817/pcs; Subtotal:USD165.44

Lead Time: 5 Business Day + 3 Business Days Shipping

I understand a four layer 0.032″ board will be a lot more expensive I just wanted to point out that there could be cheaper alternatives.

I work at a PCB factory in Sweden, we are however not cheap, it’s not impossible though I might be able to squeeze something like this in (one or two boards) at no other cost than the shipping price if there are other boards made with the same configuration (thickness, copper thickness, layers, material).

In my experience the shipping costs for various parts are what tends to make things more expensive, having a single supplier for all parts can be more economic than ordering from here and there even if the individual parts are cheaper.

Gideon is having trouble sourcing microSD card connectors in the same type that he has been using for the 1541U-II. Make sure you choose components that are available in the near future as well if you intend to do more than one batch (I guess it depends on how many is sold). 😉

Sounds like it will be expensive, do you have any aim regarding the cost?

Sounds to me a Spartan-3 should be enough. Can’t you download an entire VIC-20 emulation in one of those? You’d need to know how of course, don’t have those skills myself, made a 8×8 multi color LED battleship game with sampled sound effects some years ago that’s about it.